Service

ALWAYS BE PREPARED FOR A POWER OUTAGE

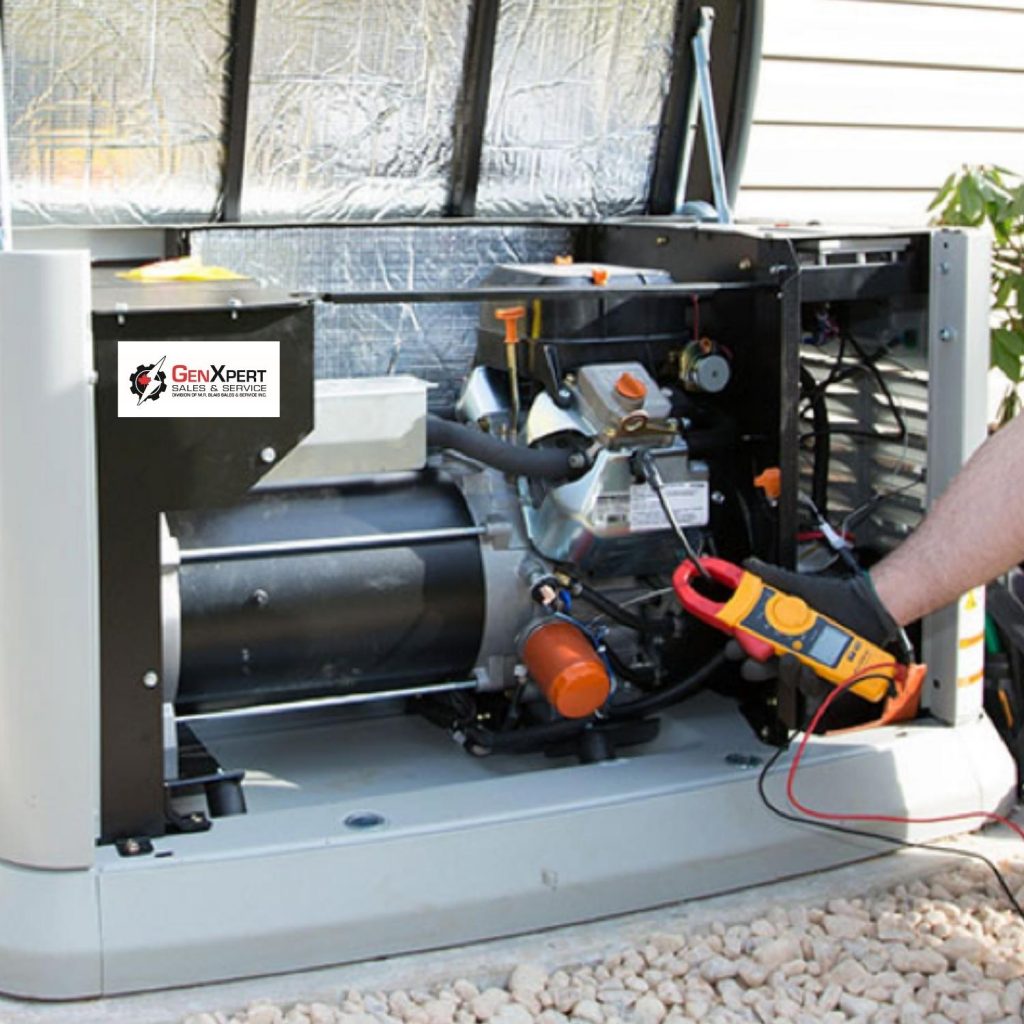

Why perform generator maintenance on a yearly basis?

One of the best ways to ensure a long-term, reliable operating life of your generator is to implement a regular, scheduled, and customary “Preventive Maintenance Program”. With a qualified generator expert, you could conceivably see that your equipment lasts 20 to 30 years if it receives regular maintenance. We recommend this essential service to all our clients. The fact is, maintenance usually prevents costly repairs and saves money long term.

Whether a generator unit is powered by diesel, gas, or gaseous fuels *(propane or natural gas) is roughly the same. The typical maintenance cycle includes a general inspection followed by scheduled inspection and service of the following critical systems:

STEP 1 – YEARLY MAINTENANCE

Your GenXpert will perform maintenance on the “5 Core Systems” of your generator

- Fuel system (diesel fuel requires more maintenance)

- Coolant system

- Lubrication system

- Air system (combustion and cooling air)

- Starting system (batteries and charger)

- Alternator (a frequently overlooked item)

- Transfer switch (another often-overlooked item)

STEP 2 – COMPREHENSIVE INSPECTION

Then, the GenXpert specialist will focus on the 2 overlooked elements of an inspection

GenXpert will test and inspect the following: Winding Resistance and Cleaning Winding

1. ALTERNATOR – 3 Biggest Enemies

- Dirt – Dirt can and will block the heat transfer that is required for winding down and cooling

- Heat – Overheating will cause unnecessary stress on the engine and all its systems and reduce power altogether

- Moisture: Added moisture can affect and cause the winding to short to each other

2. TRANSFER SWITCH * What is necessary to transfer power to and from the hydro to the generator

- The Transfer Switches can present more challenges to inspect, maintain and demand specific know-how

- A thorough annual inspection will demand that your GenXpert be turning off all power to the switch.

- Coordinating a “planned outage” for a specific time on a weekend or during the night may be recommended

STEP 3 – PREVENTIVE MAINTENANCE PROGRAM

Conclusively, GenXpert will execute their “10-Point Preventive Maintenance” tasks.

- Change oil and filter.

- Verify the fuel filter.

- Verify the air filter.

- Clean the crankcase breather.

- Change spark plugs.

- Check coolant concentration.

- Flush the cooling system (as needed).

- Perform load bank test if necessary

- Fuel testing & reconditioning (diesel-fueled units only).

- Remove water from fuel tank (diesel-fueled units only).